ISAE-Supméca (permanents) :

|

Jean-Yves CHOLEY

jean-yves.choley@isae-supmeca.fr Professor at ISAE-Supméca, Saint-Ouen-sur-Seine, France Member of Laboratoire Quartz, within the Mechatronics and Multiphysics Systems Engineering (IS2M) research team

Jean-Yves Choley obtained a Master degree in Mechanics and Automation and a Master of Advanced Studies in automated manufacturing from ENS Cachan, France (recently renamed ENS Paris-Saclay). He obtained a Ph.D. degree of Industrial Engineering in 2005 from Ecole Centrale Paris, France (recently renamed CentraleSupélec), related to ISO GPS mechanical tolerancing and 3D metrology. He gained industry operational experience (1986-1988) in systems engineering and quality & reliability at Arianespace company, Kourou (French Guyana), France, working both on ground facilities and satellites launchers Ariane 1 to 4. Professor at ISAE-Supméca, France, responsible of IS2M (Ingénierie des Systèmes Mécatroniques et Multiphysiques) research team of Quartz laboratory, he is in charge of research and teaching activities focusing mainly on tools, languages and methodologies for the collaborative design of complex systems such as mechatronic systems, CPS (Cyber-Physical Systems) and CPPS (Cyber-Physical Production Systems). In the past 10 years, he mainly focused on Model-Based Systems Engineering (MBSE), Model-Based Safety Assessment (MBSA) and the digital twin concept, together with multiphysics modeling for the collaborative design of safety critical mechatronic systems, such as autonomous vehicle and factory of the future production systems (4.0 and 5.0). |

|

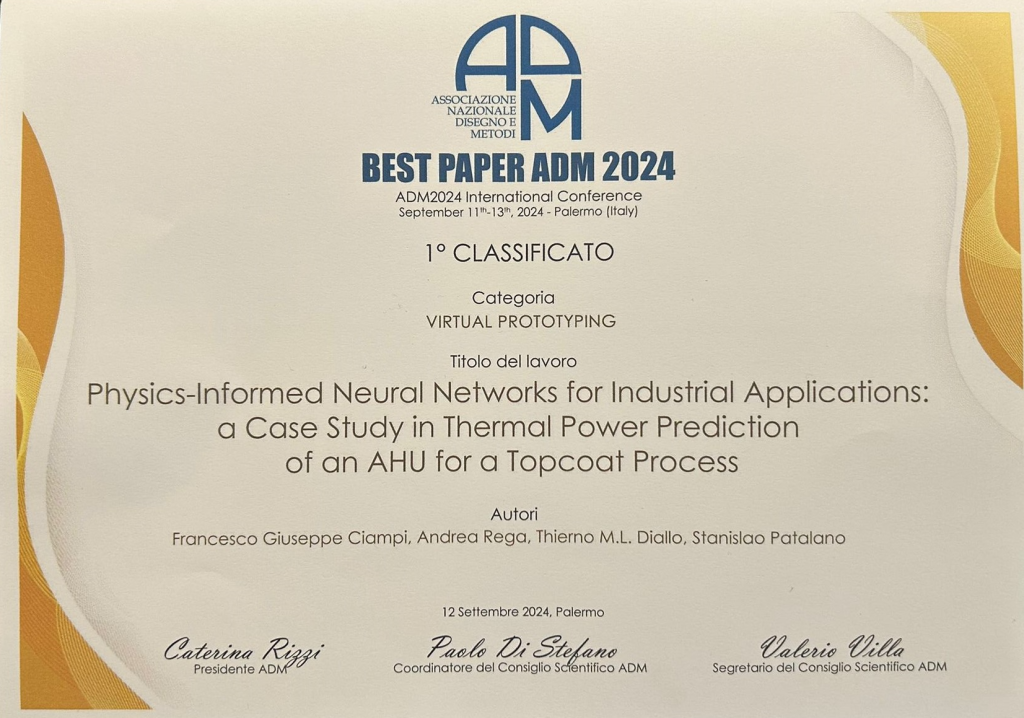

Thierno DIALLO

thierno.diallo@isae-supmeca.fr Associate – professor at ISAE-Supméca, Saint-Ouen-sur-Seine, France Member of Quartz Laboratory, within the Mechatronics and Multiphysics Systems Engineering (IS2M) research team

Dr. Thierno DIALLO is Associate Professor at ISAE-Supméca since 2016. He holds an engineering degree in Industrial Engineering (ENSA, Fès 2011), a Master Degree in Artificial Intelligence and Decision Support (INSA, Lyon 2012) and a PhD in Industrial Engineering (Claude Bernard Lyon 1 University). His research activities focus on the exploitation of Big Data in industry applied to prediction and diagnosis, decision support methods and the management of the adaptability and scalability of Cyber-Physical Production Systems (CPPS). |

|

Moncef HAMMADI

moncef.hammadi@isae-supmeca.fr Associate Professor – HDR ISAE-Supméca, Saint-Ouen sur Seine, France Laboratoire Quartz/ Mechatronics and Multiphysics Systems Engineering (IS2M) research team

Moncef Hammadi holds an MSc degree in Mechanical Engineering from the National Engineering School of Sfax, which he obtained in 2008. He earned his PhD in Industrial Engineering from Ecole Centrale de Paris (University of Paris Saclay) in 2012. In 2021, he achieved the qualification to supervise research from the University of Technology of Compiègne (UTC). Since 2012, Moncef Hammadi has been serving as an associate professor at ISAE-Supmeca Paris. His research activities are part of the Ingénierie de Systèmes Mécatroniques et Multiphysiques (IS2M) team within the QUARTZ laboratory. His focus encompasses complex systems modeling, multi-physics simulation, multi-disciplinary optimization, and inter-disciplinary collaborative design methodologies for the development of mechatronic and cyber-physical systems. |

|

Faïda MHENNI

Associate Professor at ISAE-Supméca, Saint-Ouen sur Seine, France. Member of Laboratoire Quartz, within the Mechatronics and Multiphysics Systems Engineering (IS2M) research team

Faïda MHENNI received an engineering degree in electromechanical engineering in 2002 from ENIS (National Engineering School) in Sfax, Tunisia. She also received a MSc degree in mechanical engineering in 2004 from ENIM (National Engineering School), in Monastir, Tunisia. She holds a Phd degree in mechanical engineering in 2010 from the ENIM (National Engineering School), in Monastir, Tunisia and a Phd in Industrial Engineering in 2014 from Ecole Centrale de Paris (currently University of Paris Saclay). Her main research topics are systems engineering (MBSE), Safety, digital twin, mechatronic design and multi-physics conceptual design. |

|

Dr. Ing. HDR (accreditation to supervise research) Olivia PENAS

Research engineer, Research Deputy Director ISAE-Supméca, Saint-Ouen sur Seine, France Laboratoire Quartz/ Mechatronics and Multiphysics Systems Engineering (IS2M) research team

Olivia Penas received his MSc in Material Science Engineering in 1999, PhD in Physics of Materials (Smart Space composites) in 2002 from INSA Lyon (France), and HDR degree (French habilitation to supervise PhD) in 2019. She was the Head of the Research Technical Support Teams of Supmeca in 2006, then the Deputy Director of LISMMA Laboratory in 2013 and Research Deputy Director of Supmeca (Paris) since 2015. Her main research topics are systems engineering (MBSE), agility, knowledge management/ontologies, digital twin, design metrics, mechatronic design and multi-physics conceptual design. |

|

Régis PLATEAUX

regis.plateaux@isae-supmeca.fr Associate Professor ISAE-Supméca, Saint-Ouen sur Seine, France Member of Laboratoire Quartz, within the Mechatronics and Multiphysics Systems Engineering (IS2M) research team

Régis Plateaux obtained a Master of Advanced Studies in automated manufacturing from ENS Cachan, France (today ENS Paris-Saclay). He obtained a Ph.D. degree of Industrial Engineering in 2011 from Ecole Centrale Paris, France (today CentraleSupélec), related to the guaranty of the consistency and the continuity during mechatronic design process by the means of analogy, topology and algebraic topology. Associate Professor at ISAE-Supméca, France, he is head of the Mechatronic and Complex System (MSC) department. His teaching activities address tools, languages and methodologies for the collaborative and agile design of complex systems, on Model-Based Systems Engineering (MBSE), the digital twin concept, and multiphysics modeling. His main research topics focus on:

|

|

Nourhène ABDELJABBAR

nourhene.abdeljabbar@isae-supmeca.fr Dr. Ing. ISAE-Supméca, Saint-Ouen sur Seine, France Quartz Laboratory / Mechatronics and Multiphysics Systems Engineering (IS2M) research team

Main research topics focus on :

|

|

Romain DELABEYE

romain.delabeye@isae-supmeca.fr Associate Professor ISAE-Supméca, Saint-Ouen sur Seine, France Member of Quartz Laboratory, within the Mechatronics and Multiphysics Systems Engineering (IS2M) research team

Romain Delabeye is an Associate Professor at Quartz Laboratory. He received a Master’s degree in mechanical engineering, mechatronics and complex systems from ISAE-Supméca, France, and a Master’s degree in autonomous vehicles dynamics and control from Cranfield University, UK. In 2024, he obtained a Ph.D in mechanical engineering and signal processing from Paris-Saclay University and CentraleSupélec, focusing on the unsupervised separation of actuator signatures from non-intrusive sensors in industrial processes, and applications to the energy sustainability of heterogeneous systems. His main research topics focus on:

|

|

Imane BOUHALI

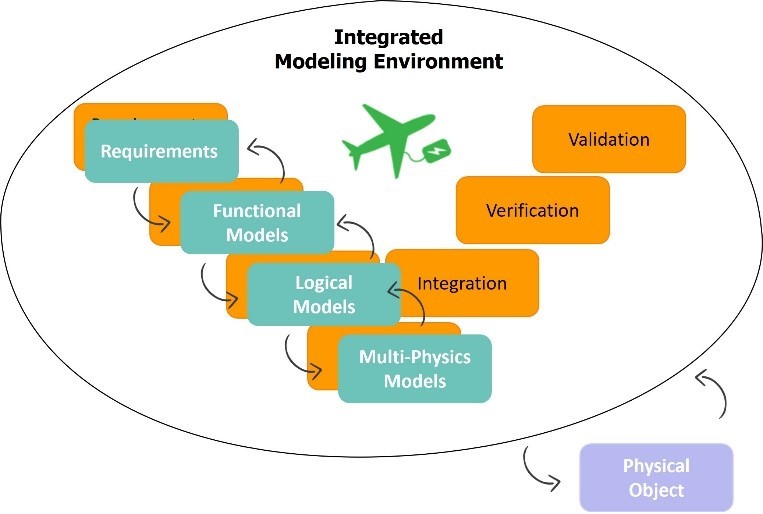

PhD student INSA CVL, Bourges, France & ISAE-SUPMECA, Saint Ouen sur Seine, France & Safran Seats, Issoudun, France. Imane Bouhali is a mechatronic engineer and a third-year Ph.D. student at the National Institute of Applied Sciences (INSA Bourges), in collaboration with the High Institute of Mechanics (ISAE-SUPMECA Paris). Imane completed Engineering degree at Mechatronics, in addition of a Master degree from the High National School of Paris Saclay (ENS) at Complex Systems Control. Her research explores the multi-physics simulation, tackling discipline-specific modeling and co-simulation problems. In addition of the use of Model-Based Systems Engineering (MBSE) in the context of the Digital Twin concept, operated in the development process. From a practical side, Imane is working at Safran Seats company, to put her research into practice. Keywords: Digital Twin, MBSE, Mechatronics, Mulitphysics, Simulation. |

|

Grégoire GALISSON

gregoire.galisson@isae-supmeca.fr PhD student ISAE-SUPMECA, Saint-Ouen sur Seine, France Grégoire is a thermal engineer and PhD student at ISAE-SUPMECA. He has three years of experience working on multiphysics simulation methodology for designing complex systems. His research focuses on enhancing simulation accuracy and efficiency and also aims to bridge the gap between MBSE and physical simulation. Keywords : Simulation ; Thermal ; Multiphysics, MBSE, Digital Twin |